PFAFF 8303ix

Modern hot-air taping machine for welding continuous seams on water-resistant, waterproof and breathable materials

Modern hot-air taping machine for welding continuous seams on water-resistant, waterproof and breathable materials with new technical features:

NEW: Tape cutter for widths from 8 - 30 mm

- Trimming of the seam tape becomes unnecessary (welding from the beginning of the tape), resulting in a considerable reduction of the tape used. The tape cutter is electronically controlled, with precision adjustment for an exact setting.

NEW: Maximum Output - Less material, energy and air consumption

- 20% increased productivity in comparison to other tape welding machines. Up to 15% reduction of the amount of tape used compared to standard machines. Less energy and air consumption thanks to new, optimised nozzle.

Reproducible quality / High process reliability

- All relevant process parameters can be programmed and saved via touchscreen

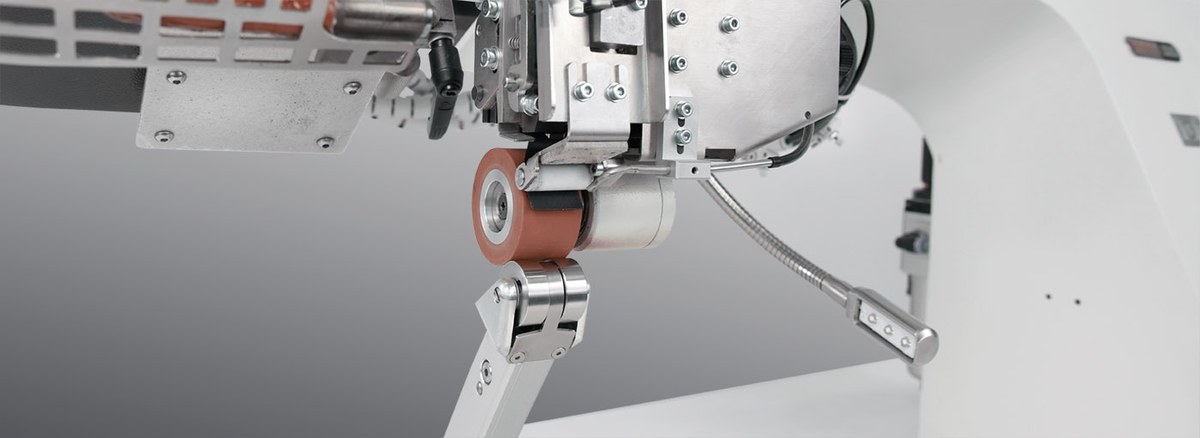

Differential feed for highest seam quality

- Two separate drive motors for the top and bottom feed roller guarantee an optimum adaptation to the operation (e.g. smooth seams or fullness for formed parts)

Variable post- and roller concept

- Customer application in focus! Variable post concept (post width 25, 28 and 32 mm and post positions like post from front, vertical post and post from back – depending on the operation). Several roller diameters are available: 45 mm for standard operations, 25 mm for shoes and automotive (narrow curves) applications

NEW: Small post, 25 mm diameter

Small post with central belt drive for applications with very small radii.

Applications

Specifications

Sealing temperature: max. 650 °C

Sealing speed: max. 7 m/min (standard), option up to 20 m/min available

Width of nozzles: 10 - 30 mm (others available)

Air consumption (6 Bar): approx. 150 l/min

Connection voltage: single-phase a.c. 230 V, 50/60 Hz

VdCAlJFzzd8

8303i